FlexiCAM GmbH

Booth number: J.5.3.2

www.flexicam.com

About us

FlexiCAM stands as one of the industry leader with extensive expertise in the design and manufacturing of CNC machining centers. Our unwavering commitment to excellence in production and customer service sets us apart in the industry.

Specializing in 3, 4, and 5 Axis CNC machining solutions, FlexiCAM caters to a diverse array of industries, placing emphasis on Aerospace, Boat building, automotive, railways, and more. Our machining capabilities extend to various materials, including Aluminum and Composites, aluminum extrusions, ACP, ACM, facades, plastics, acrylics, as well as models and pattern making.

In addition to our standard machine series, FlexiCAM takes pride in offering bespoke solutions tailored to meet the unique requirements of customers, particularly in the aerospace sector where intricate geometries demand specialized machining. Our commitment to technological innovation ensures a continuous evolution of our product line, maintaining FlexiCAM's position at the forefront of CNC technology.

At the core of our mission is a dedication to customer satisfaction, ensuring a seamless experience from the initial engagement to project completion. FlexiCAM's enduring pursuit of quality is a testament to our commitment to exceeding industry standards and expectations.

Address

Benkertsweg 9

97246 Eibelstadt

Germany

E-mail: info@flexicam.com

Phone: +49 9303 90810

Internet: www.flexicam.com

HFZ, Sharjah

P.O. Box 41752 Sharjah

Germany

E-mail: info@flexicam.com

Phone: +9716 5263307

Internet: flexicam.com

Contact person:

Mr Ashfaq Qadri

Business Manager

E-mail: aqadri@flexicam.com

Phone: +971 50 3686758

Mr Raqeeb Quarashi

Technical Manager

E-mail: rquarashi@flexicam.com

Phone: +971 50 5089986

Products & Services

FlexiCAM specializes in designing and manufacturing top-tier custom CNC Machining Centers, including our renowned line of CNC Routers & Machining Centers. Our team of engineers is adept at tailoring custom solutions to precisely match your unique manufacturing needs.

We cater to a diverse array of industries, notably prioritizing aerospace, boat building, railways, composites, aluminum production, facade fabrication, woodworking, plastics manufacturing, and the sign making sector.

FlexiCAM Piranha

The FlexiCAM's Piranha 5-Axis CNC machining center is specifically designed for high-speed machining of large-sized workpieces such as manufacturing patterns, moulds, jigs, prototypes, and trimming of large-scale composite parts in the aerospace industry. The machine is capable of handling sizable workpieces, with a work envelope that measures up to 60 meters in length, 7 meters in width, and 5 meters in height.

The Piranha features powerful spindles and can operate using either the FlexiCAM Advanced Control System (ACS) or an industry-standard Siemens or Fanuc control system. It is particularly effective in processing large parts that require extended axis travels, a long stroke, and considerable height under the gantry.

To enhance the machine's efficiency, FlexiCAM provides a range of additional options, such as multiple gantries, optical (laser) or mechanical probes, palette changers for workpieces, dust collection systems, and other features.

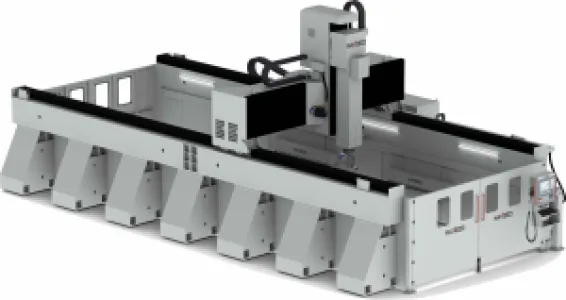

FlexiCAM Ultimate

The FlexiCAM Ultimate is a heavy-duty and high-performance workhorse with a single-piece base frame offering many different work areas of up to 3 m x 6 m. It is designed and tested for customers with high production requirements and it is capable of 3- to 5-axis machining using the FlexiCAM Advanced Control System (ACS) or an industry-standard Siemens or Fanuc control system. The FlexiCAM Ultimate offers a large range of spindles of up to 50 KW, a rotary tool changer, a high-performance chip extraction system, etc., to address specific application requirements.

The FlexiCAM Ultimate offers various work table designs, including a specialized Vilmill vacuum table. Vilmill, positioned between the workpiece and the router's vacuum table, enables effective machining of materials such as aluminum, plastics, copper, and composites. The machine can also be customized with a pressure foot and detagging system for stack sheet machining in the aerospace sector.

FlexiCAM Xtreme

The FlexiCAM Xtreme is a state-of-the-art CNC machining center that boasts a modular design, making it an ideal choice for a range of industries, including aerospace, boat manufacturing, RV production, trailer and mobile home building. With the ability to work with unlimited lengths and widths of 3, 4, and 5 meters, the Xtreme is perfect for large panel processing, large format part cutting, and production line manufacturing.

The machine’s large format capabilities enable manufacturers to produce complex parts and components with precision and accuracy, while its modular design means that the machine can be easily modified and upgraded to meet changing production needs. In summary, the FlexiCAM Xtreme is a cutting-edge CNC machine that offers unparalleled versatility, flexibility, and performance.

FlexiCAM XL

The FlexiCAM XL has been specifically engineered to cater to the needs of high-production shops, and is equipped with powerful AC Servo drive system as a standard feature.

These machines are highly suitable for demanding applications such as machining non-ferrous metal, solid surfaces, and plastic parts. They have been designed to operate in production-type environments and are capable of handling a broad range of manual tool change and automatic tool change spindles to meet specific application requirements.

The XL's foundation is constructed using heavy welded tube on tube design, creating a single, sturdy unit. The machine is customizable with various options available from FlexiCAM, including but not limited to, Rotary Axis, C-Axis, Siemens and Fanuc Controls, I-Cut Vision, Auto Lubrication, and more.